NSI ORIFICE PLATE ASSEMBLY (OPA)

The NSI Orifice Plate Assembly (OPA) is everything you need for a successful orifice plate flow measurement solution.

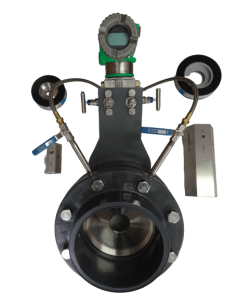

Neal Systems has partnered with our suppliers to design and package a complete orifice plate flow measurement solution – the NSI OPA series. This kit comes standard with the flow element, mounting hardware, flow meter, and sizing reports for your specific application.

Features

Transmitter

Transmitters with high accuracy are required for the most demanding applications, and with an accuracy of up to ±0.025% of reading, the IDP50S pressure transmitter fits the bill. These transmitters offer embedded FoxCal™ technology and multiple points of calibration, which allow you to benefit from wide rangeability and one of the best reference accuracy turndowns on the market.

HART digital outputs, FOUNDATION Fieldbus digital outputs, 4 to 20 mA outputs

Accuracy up to ±0.025% of reading

Response time of 125 ms

Innovative and dynamic FoxCal™ technology allows the transmitter to store multiple factory-preset calibration ranges up to 10:1 turndown, while maintaining published accuracy without the need for field calibration

Ability to locally configure the device with pushbuttons on the optional local display

Ability to remotely communicate with and configure the device using the device descriptor (DD), Device type Manager (DTM), or the Field Device Integration (FDI) package

Simple, elegant sensor design with very few parts achieves exceptional reliability

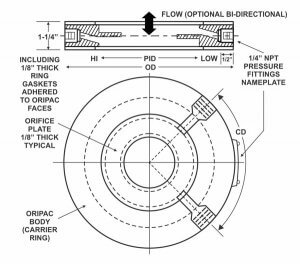

ORIPAC

Integrated metering taps are properly located and predrilled. The ORIPAC installs easily with standard ANSI flanges, so that traditional orifice flange unions are eliminated. No drilling or tapping is required for installation.

The full faced integral gasket comes pre-attached to the ORIPAC making alignment easier during installation.

The ORIPAC is self-centering within standard flanges, which means the ORIPAC O.D. sits snug within bolt circle of specified flange rating insuring concentricity. No centering devices or additional components are required for installation.

“Corner” type metering taps are used for compatibility with established coefficient accuracy values.

Custom bore size is available to produce any specific differential pressure.

Metering taps are drilled “straight through” to the pipe I.D., making them easily accessible and cleaned using pipe cleaner or rod out kit.

Assembly Kit

The assembly kit comes custom designed for the application and includes:

- A Flow Sizing Report detailing range and accuracy data for the specific application and orifice plate bore diameter.

- The ORIPAC from Lambda Square with the specific bore and flange dimensions.

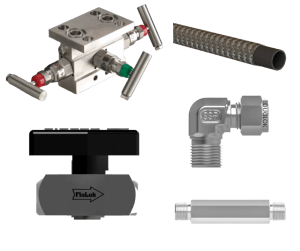

- The Mac-Weld 3-Valve T-Type instrument manifold

- The connection kit with the hex nipple extension, isolation valve, armored flexible Carbon PTFE chemical tubing with Static dissipation, and a tube-fitting elbow for connection to the manifold.

- IDP50S dP flow measurement transmitter from Schneider-Electric with the range and output parameters pre-configured to match the flow sizing report.

- The field mounting plate with cutouts specific to the transmitter and flange bolts for mounting the transmitter to the flange without any additional hardware.