Application Note: Water Infrastructure Data Management

December 13, 2022 | Application NotesMunicipal: Water / Wastewater / Landfill

Are you looking to improve cyber security for your remote operations? The SCADAPack 474 by Schneider Electric has you covered. This latest generation of SCADAPack Smart RTUs is optimized for remote operations, this is the newest model to be introduced in this series.

The SCADAPack 474 is simple, efficient and rugged. It enables compliance with TSA Security directives and improves cyber security for remote applications.

Simple: The RemoteConnect configuration software facilitates configuration, logic development, data logging, and diagnostics in a single application, helping to reduce costs and overhead associated with maintaining multiple software applications for managing a single device.

Efficient: The Logic Editor within RemoteConnect software is based on EcoStruxureTM Control Expert software components, allowing for code reuse and sharing between Schneider Electric ModiconTM PLCs and SCADAPack Smart RTUs.

Rugged: Designed with Cybersecurity and ruggedized communications in mind, SCADAPack 474 hardware features conformal-coated boards and wide operating temperatures of -40…70 °C (-40…158 °F). Class I, Div. 2 and Zone 2 hazardous area certifications are included.

Interested in learning more? Contact us about the SCADAPack 474 today.

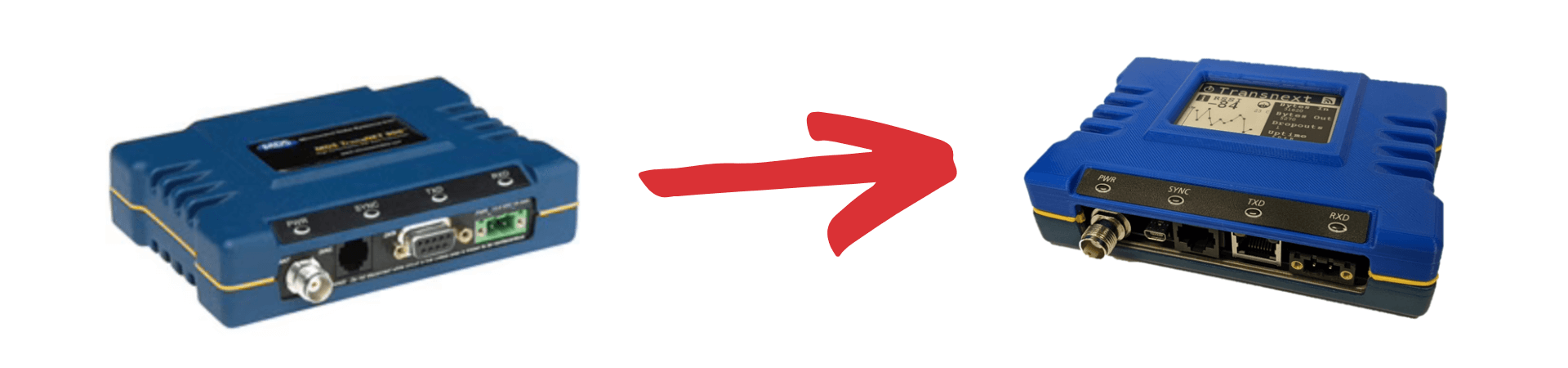

GE MDS has announced a March 31, 2023 launch date for the next generation of unlicensed 900MHz transceivers, TransNEXT. GE MDS is planning to accept TransNET orders until December 31, 2022. Please consider purchasing spares soon to cover the three month gap.

Due to this obsolescence GE MD will be launching the GE TransNEXT.

This is the next generation of unlicensed 900Hz.

Why choose TransNEXT?

Key Features:

Interested in placing TransNET orders prior to obsolences or getting more information from our team on the TransNEXT?

Neal Systems is here to service all your wireless communication requirements!

The PMC VersaLine VL2000 Series submersible level transmitters are specifically designed for use in wastewater, pump/lift station applications.

The ceramic sensing element provides a rugged flush open face design which avoids clogging or sludge build up from the materials often encountered in wastewater. The stainless steel construction will satisfy most applications, but an option of Titanium is available where the chemical environments dictate. The standard polyurethane vented cable is molded to the transmitter providing the highest integrity waterproof assembly well proven in thousands of installations worldwide. FEP cable is available as an alternate for harsh environments. A feature of the VL2000 Series is full scale ranges as low as 10” WC.

Applications Include:

Surface and Run-Off Water

Process Plant and Water Run-Off Monitoring

Sewage Lift Stations – Ceramic Clog Free

Paper Making Machine

Specifications:

Ranges: Full Scale (Zero based)

0-10, 20, 30, 50” WC

0-1, 5, 10, 15, 30, 50, 100, 150 psig

Other ranges and pressure units can be specified.

±0.1%, ±0.25% Accuracies

All welded 316L SS or Titanium

4-20 mA, 2 wire output

Molded polyurethane

For Zero Maintenance:

In order to reduce on site maintenance PMC has developed the MP 11 Moisture Protection Reference Volume. For vented gauge transmitters this provides a total isolation to the atmosphere by using a custom bladder while maintaining the high performance of the transmitter. This changes volume with Barometric pressure. Totally maintenance free.

For more information on this or similar products, reach out to our expert team of engineers HERE!