Company News

May 5, 2022 | Company News

V10.04 released for nanodac recorder/controller

Eurotherm by Schneider Electric TM is pleased to announce the release of V10.04 product firmware for the nanodac™ recorder/controller. This is a minor update to increase the number of supported Modbus clients from 4 to 6.

iTools Engineering Studio

A new IDM installer supporting nanodac recorder/controller V10.04 firmware will be available to download and install.

Availability

All units shipped after the 23rd

May 2022 will be fitted with V10.04.

How will my customer get technical support?

For Technical Support: to contact us for advice, either by telephone at 215-968-7577 or via email at sales@nealsystems.com.

May 3, 2022 | Company News

Case Study: Improved Quality and Range of Products for BrightPet Nutrition Group

Background

BrightPet Nutrition Group Manufactures Premium and super premium pet foods for U.S. and international markets. Its top-of-the-line ingredient options and state-of-the-art American manufacturing operations ensure the quality of every recipe they produce. A pioneer in the organic pet food space, BrightPet owns the first organic-certified plant in the U.S.

and is the only USDA organic certified pet food producer on the east coast. BrightPet manufactures dry dog and cat foods for a number of the most respected super-premium branded customers in the industry. The company is also a supplier of private label brands to its retail customers.

BrightPet approached Thayer Scale to help upgrade their existing pet food batch mixing system.

The original system consisted of a stainless steel tank on legs with a dual hose peristaltic pump with an inverter drive. The pump discharged through a 2” sanitary tube line and passed through a 1” coriolis style flow meter on its way to the mill/extruder.

At the time, the system pumped a homogenized slurry of fresh frozen meat, vegetables and water to the mill at rates of around 5 – 40 lbs/min depending upon the recipe and the production rate of the pet food. The speed of the pump was manually adjusted to achieve the desired rate, but the flow rate signal tended to be noisy and maintaining a steady consistent feed rate was problematic.

Challenge

BrightPet hoped to improve the quality and the range of products that could be produced by modifying the equipment to become more efficient, less noisy, more accurate and repeatable.

A New Challenge Arises

The pump speed control was tied to a central control system that now allowed the operator to enter the desired flow rate from the recipe and the feed back from the flow meter allowed closed loop control of the pump speed. This system worked well at times, but very poorly at other times due to inability of the coriolis flow meter to provide an accurate flow rate reading on the slurry. Since the slurry is quite viscous (similar to soft ice-cream) and near the freezing point, the meter would not see the slurry as homogenous and the flow through its two internal tubes was not equal.

The end result was that the signal from the flow meter was erratic and resulted in poor operation of the system. A new, more consistent system needed to be implemented that would allow for a stronger, more consistent reading.

The Thayer Scale Solution

After looking into other types of flow meters and not finding any that looked like they would provide an accurate and reliable output, the decision was made to go with a Loss-In-Weight approach. After having good results with Loss-In-Weight powder feeder and five weigh belt feeders for the dry pet food ingredient batching system, the team decided to look at a cable scale Loss-In-Weight system for the meat slurry.

Implementation

The exclusive Thayer Scale “FMSS” (Force Measurement Suspension System) design provides extremely high sensitivity. Feeder and weigh hopper “dead load” are mass-counterbalanced so that only material weight (live load) is measured. This feature helps assure excellent control in “noisy” environments.

All of the articulate parts of the scale mechanism are supported from “axially inextensible, but laterally yieldable” suspension elements (stainless steel pre-stressed aircraft cable), which are arranged to hang freely, thereby avoiding any appreciable spring or hysteresis effect, variation in mechanical advantage, or binding due to imperfect leveling.

Because of this unique mechanical property of the force transmission system, any laterally directed forces and shock on the scale or its supported feeder cannot cause destructive shear and bending stresses to develop in the elements themselves or at the load cell junction. The system, being yieldable in the lateral direction, is therefore effectively and completely protected by using laterally placed “stops” in proximity of the weighed structure.

The team removed the legs from the meat slurry tank and mounted the tank on the scale. The pump was supported off the bottom of the tank and a piece of sanitary flex hose was installed from the pump discharge to the fixed 2” sanitary piping. The Loss-InWeight controls are connected to the plant control system via an Ethernet connection allowing the control system to set the desired feed rate and to monitor the operation of the system. The Loss-In-Weight controls provide a 4 – 20 ma signal to operate the pump at the required speed, and controls the automatic refilling of the meat slurry tank.

Today

The system was commissioned in July of 2010 and today remains in successful operation. The combination of the progressive cavity pump and the cable scale and controls provides a very steady and accurate flow of the meat slurry to the mill.

This has greatly reduced the variation in the pet food as it is produced and allows for faster startups and less frequent adjustments by the mill operator. The system takes less than 60 seconds to get within a 1% accuracy of the desired feed rate after startup or changes in set point. The system has worked very well over the entire operating range of 5 to 65 lbs/min and is immune to changes in the flowability or makeup of the slurry.

March 7, 2022 | Company News

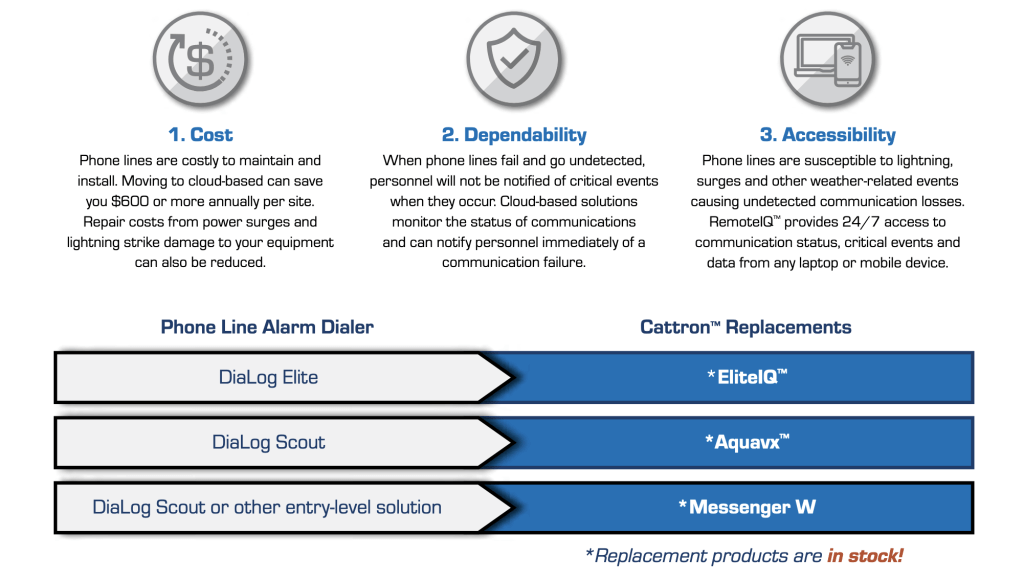

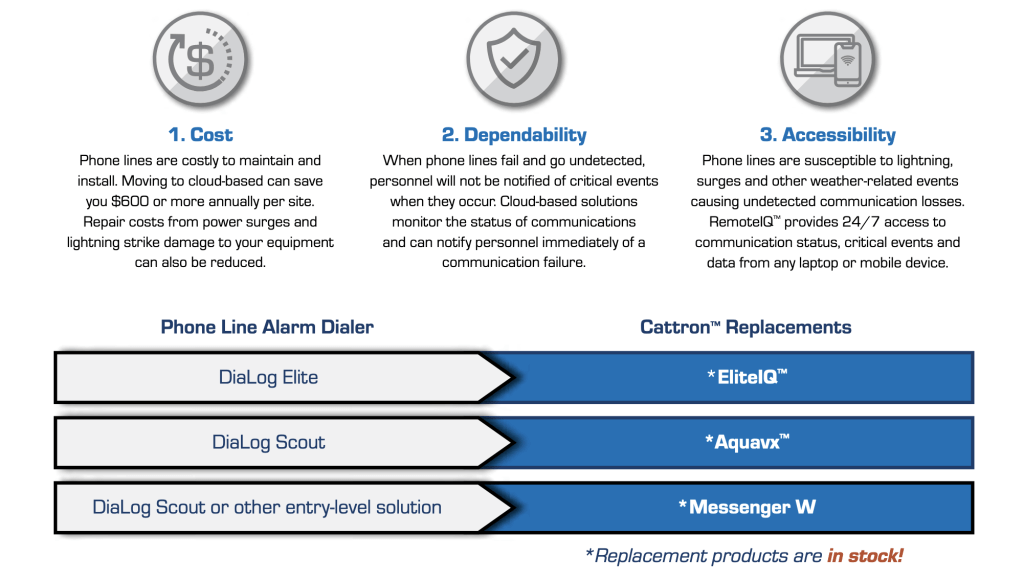

Make the Switch!

Don’t get left behind and become susceptible to lost communications with legacy phone line alarm dialers.

Below are the Top 3 Reasons to switch to a wireless, cloud-based monitoring and control solution for your water

and wastewater applications.

Interested in learning more? Contact Peter Jackson: PJackson@nealsystems.com

February 23, 2022 | Company News

AT&T shut down its 3G wireless network yesterday and Verizon Wireless is in the process of shutting down their 3G wireless network.

The NSI Neal Systems team is available and has the equipment, knowledge and experience to quick restore your remote asset data communications and provide for all of your industrial wireless needs!

February 10, 2022 | Company News

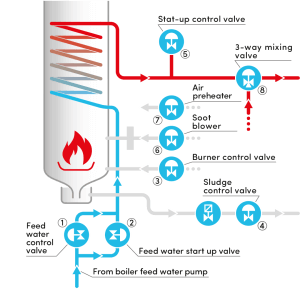

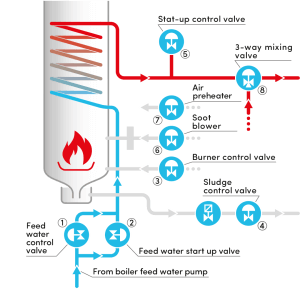

With ARCA Valves you will find the right control valve for each process step in the boiler of the power plant.

1) Main/feed water control valve

With this control valve, the level in the boiler drum is regulated so that boiler feed water is continuously available in the boiler for steam generation. In order to compensate for the difference between the characteristic curve of the feed water pump and the operating characteristic of the boiler system, the characteristic curve of the feed water control valve must be designed accordingly.

2)Filling/feed water control valve

The boiler drum is filled by this control valve when the system is started up. Since a large differential pressure and cavitation have to be mastered during start-up, this valve is subject to high stress and thus wear. Therefore, this often small valve is equipped with a hard multi-stage trim and is located in parallel with the main feed water control valve, which must then be designed for maintaining the level.

3) Burner control valve on the boiler

This valve regulates the supply of natural gas to the gas burner or the heating oil to the oil burner on the boiler. During gas operation, the valve regulates to maintain the defined control characteristic and reduce noise. When heating oil is used, this valve functions as an overflow facility and holds the pressure upstream of the oil burner nozzle constant.

4) Sludge control valve

This valve quickly opens for a brief moment to drain a small quantity of boiler feed water for desludging the boiler water drum. Hard internal parts are required to withstand the high differential pressure, cavitation, and abrasion that prevail. The seat faces of this control valve are subject to wear, which is why we recommend installing an additional shut-off valve here.

5) Boiler start-up control valve

The start-up control valve typically blows steam through a silencer system into the atmosphere when the boiler plant is started. Since the steam expands with a high-pressure reduction, this valve usually has an asymmetric design.

6) Soot Blower Control Valve

The walls of the heat exchangers in the boiler are steam-cleaned of soot particles to optimize heat transfer efficiency inside the boiler. To this end, soot blower control valves feed live steam to the soot blower nozzles with minimum actuating time.

7) Air preheater control valve

The burner air is preheated to optimize the effectiveness of the combustion process. The temperature of the burner air is determined by the steam fed to the air preheater via this control valve.

8) 3-way mixing valve

Superheating the steam of the steam turbines while they are running increases plant efficiency and prevents the turbine blades from becoming damaged by condensed drops of liquid. For better energy utilisation of the generated steam, secondary overheating is installed in power plants with higher steam pressures. The heat transferred to the superheater varies greatly due to fluctuating loads and soot deposits in particular. The temperature of the superheater must therefore be regulated. The superheated steam is passed through a pipe coil by means of the 3-way mixing valve, which is located in the water-filled part of the steam drum. The colder drum water with the saturated steam temperature thus cools the superheated steam.

8) Boiler injection cooler

Another way of controlling the superheater temperature is usually implemented in new systems by injecting boiler feed water with a controllable injection cooler.