Company News

New Distribution Partnership: AUTOMATION SERVICE!

October 27, 2020 | Company NewsNeal Systems forms a distribution partnership with Automation Service (www.automationservice.com), which provides new and rebuilt solutions for a variety of manufacturer’s transmitters, valves, and pneumatic equipment, as well as on-site facility recycling solutions for the same equipment. Schneider Electric’s Foxboro brand recently sold the pneumatics solutions portion of their business to Automation Service, and thus Neal Systems is excited to continue to be able to provide solutions to customer who need refurbished or new pneumatic transmitters.

New Representation Partnership: ALTA SOLUTIONS!

October 27, 2020 | Company NewsNeal Systems forms a representation partnership with Alta Solutions (www.autosol.com), one of the premiere manufacturers of API-670 machinery protection systems for large rotary equipment (pumps, cooling towers, compressors, fans, motors) and turbines. Neal Systems has been in the vibration monitoring sector for almost 20 years, representing Metrix (www.metrixvibration.com) and providing dozens of vibration protection monitoring systems and 10,000+ sensors to industries such as pharmaceutical, refinery, pipeline, industrial gas, and water / wastewater. Alta brings 25 years of experience with 1000+ installations of their machinery protection and machinery monitor solutions worldwide. Alta develops and markets innovative data acquisition solutions for a variety of manufactured products and processes. They offer a complete family of signal processing products to test, measure, and analyze everything from large rotating machinery to simple roller bearings, all compliant with API-670 standards. Neal Systems is excited to team with such a powerful team of engineers and provide solutions from Virginia through New York.

Wireless Site Survey with NSI Field Service Technicians

October 14, 2020 | Company NewsNSI recently performed a wireless survey for a customer wanting to implement Elpro 945U-E radios. The radios operate as wireless ethernet nodes in the 900MHz, license free spectrum, allowing customers to significantly extend their ethernet range without running wires. The site in question needs to bring data back from multiple locations around the plant to a centralized control room and running copper or fiber wires is cost prohibitive.

NSI sent a field service technician to site with a Spectran HF-6065 spectrum analyzer in order to perform a site survey.

A site survey consists of three stages:

1. A topographical and building analysis of the site .

2. A series of background noise checks.

3. A series of radio throughput tests.

The first step uses Google Earth to analyze the topography between each of the radio installation sites. This can be done prior to or after the site visit. Whilst on site, the technician will take photographs of any obstructions such as trees, equipment (moving cranes is a good example) or buildings and locate them with GPS co-ordinates.

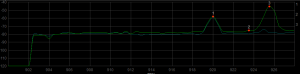

The second step utilizes the spectrum analyzer and allows the technician to take 10 minute recordings of all the radio traffic in the frequency bands in question, in this case 902 to 928 MHz. This provides details of average and peak signal strengths but also provides a waterfall graph throughout the entire test period.

Green trace shows peak noise during the analysis period

Blue line shows the average noise during the analysis period

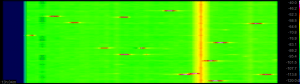

The Waterfall graph shows the background noise over time so x-axis is frequency (902-928MHz), y-axis is time period (10 minutes in this case) and the noise level is shown as a color (color scale is shown on the right hand side).

This graph shows constant transmissions around 902MHz and infrequent transmissions elsewhere in the spectrum (shown with the dark red horizontal bar).

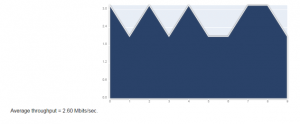

The third step is to perform an iPerf test using two back to back radios that transmit to each other whilst measuring the throughput and the error rate of the received signals. These tests are done to and from the proposed radio installation sites. The tests are performed for ten seconds and are done three times for each pair of location and the results averaged.

The radios record the results of the test and make them available in graph and summary form, looking something like this:

The results of the testing demonstrated that there is significant background noise around the 920MHz range and limited noise elsewhere in the spectrum.

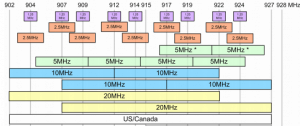

There are 28 available channels to select when configuring the Epro 945U-E radio:

• 9 x non overlapping 1.25-MHz channels

• 9 x partially overlapping 2.5-MHz channels

• 4 x non overlapping 5-MHz channels

• 4 x overlapping 10-MHz channels

• 2 x overlapping 20-MHz channels

In the frequencies shown below:

For any given signal strength the radio throughput halves as the frequency band halves so the 1.25MHz band offers 1/16 the throughput of the 20MHz band. Generally speaking, select the widest channel for which there is no interference.

For the best throughput, the 10MHz channel between 902 and 912 MHz would be selected. For the least interference, the 1.25MHz channels at either 914 or 922 MHz would be selected (these correspond to gaps in the waterfall graph).

Additional features such as whitelisting and blacklisting, encryption, transmit power and fixed noise floor are then configured. Antennas and cable type are selected based on cable run lengths, background noise levels and distance between radios, all whilst staying within the FCC’s 36dB maximum effective radiated power limit.

The biggest mistake that most users make when running into radio communication issues is to simply increase their antenna size. More often than not this does not help.

For more information on wireless and line of sight radios – check out the recent NSI Virtual Training course on “Will it ACTUALLY work? Line-of-Sight Industrial Radios“!

NJ Water Association: Instruments and Controls for Water and Wastewater Treatment

September 21, 2020 | Company NewsThe NJ Water Association partnered with Neal Systems Inc. will be providing an accredited course: Instruments and Controls for Water and Wastewater Treatment at the Denville Public Works on September 29, 2020. The course is currently filled but registration will allow you to get moved to a cancellation list!

The course accreditations are as followed:

5.0 Training Contact Hours for NJ-Licensed Water/Wastewater Operators. TCH Course# 04-092003-30

5.0 Hours toward license renewal for NJ Certified Public Works Managers: DLGS-NJWA- 202. (5.0 Tech.)

The course is designed for presentation to both beginners and experienced operation and maintenance personnel. Upon completion of the course, students will have a better understanding of how the instruments and control systems in their facility operate and how to identify and troubleshoot problems.

Pete Hutwelker will be instructing the course. Pete has work as a Service Technician, Regional Service Manager, National Service Manager, Product Manager, Systems Engineer and Business Development Manager. Pete was the Founder and General Manager of ES2 Inc. – specializing in Service and Supply of Equipment and Systems to Water, Wastewater and Solid Waste industry. He is currently employed by Neal Systems Inc. – Systems Integrator and supplier of process controls & instrumentation.

To register for the course: CLICK HERE!