< Product News

Top 7 Tips: Improve Efficiency Using Better Control

February 1, 2023There are many ways to waste time and energy during the thermal processing of food and beverage. Here are the Top 7 efficiency problems we see along with solutions for better control.

1

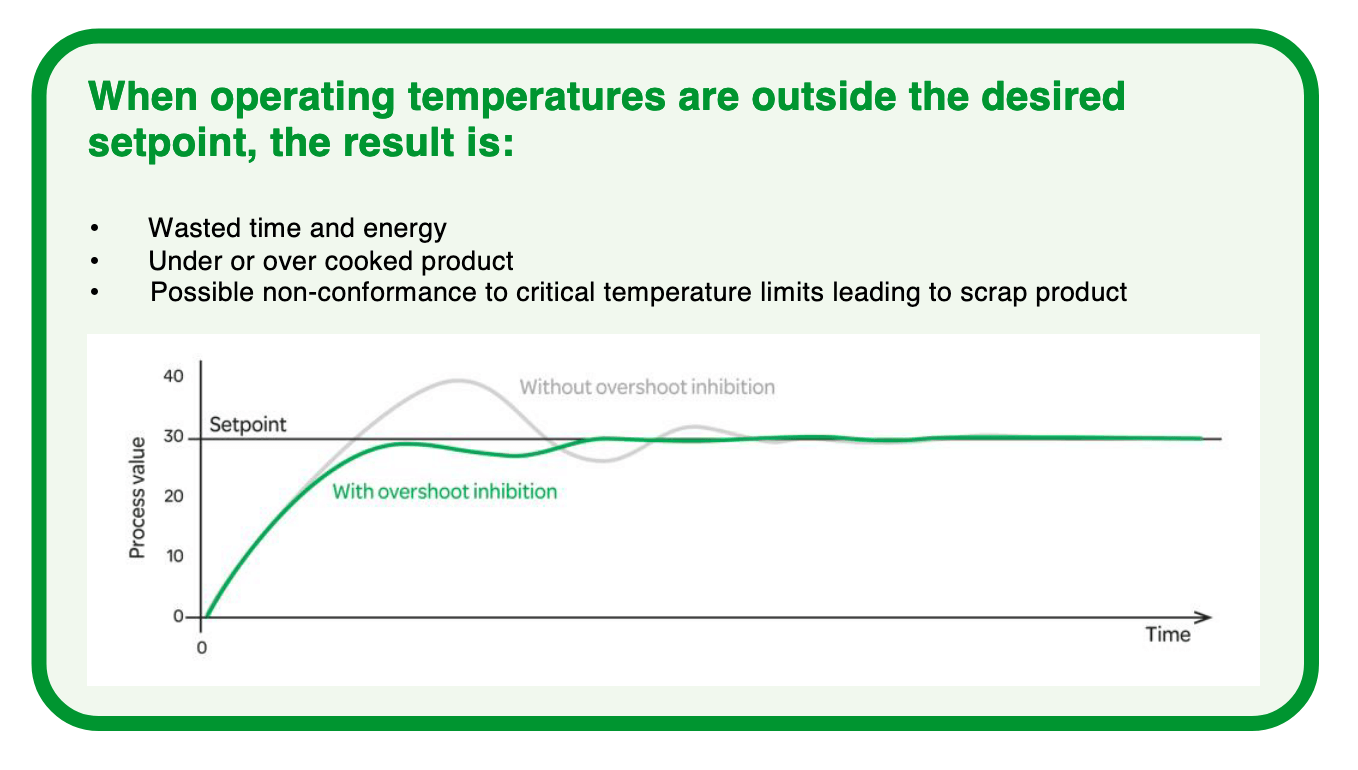

Temperature Overshoot

During cooking and cooling processes, whenever the temperature of a product overshoots or undershoots, energy is being wasted. Some products can also be damaged by overheating or overcooling and then need intervention for quality assessment. For processes where energy is being wasted in this way, one solution is to replace the simple temperature controller with a precision PID temperature controller. Intelligent models have specific algorithms embedded in the control strategy that automatically take care of common heating and cooling problems. Useful features in this case are inbuilt algorithms that stop the temperature overshooting when heating up (overshoot inhibition). Default values are typically already set for easy configuration.

2

Temperature Instability

Certain processes need critical temperature control, for example oil temperature in fryers can be difficult to control. With poor control, the oil temperature can oscillate from too hot to too cold, wasting time and energy in the process. The temperature variation can also lead to irretrievable undercooked or overcooked product creating waste and potential damage to the

oil itself if overheated.

One solution is to use a precision PID controller. Special features to look for include a set

point programmer for setting up your ideal temperature profile with temperature ramps and dwells (soaks) specified by rate or time and intelligent PID algorithms that control the temperature of the product to the specified set point. To control other setpoints at the same time, like humidity and pressure, this type of controller can typically be purchased with multi-

loop options and dedicated algorithms that aid the application. Autotune functions are available that will automatically set a range of parameters to optimise the process when enabled on your specific equipment. In this case, using a better controller will result in a consistently cooked product that maximises the life of the cooking oil – this practice is relevant to all cooking processes.

3

Product Inconsistency

Poorly controlled processes can waste time and energy through non uniform mixing, cooking and cooling of the product. One of the common problems we find is some human intervention in the process where operators are tweaking the control manually, causing uncontrolled changes to the product. In a recent example, during the process of browning waffles, where colour of the product was important, operators were found to be modifying the heating settings to get the right colour by eye. Certain operators had a knack for adjusting the controls, while others didn’t, bringing inconsistency into the finished product.

Automation of the process is better at achieving consistent results than manual intervention. A modern PID control system will ensure all of the zones in the oven are controlled to the right temperature for that particular product. Look for models with recipe functions that allow the whole setup to be saved and recalled when you need to manufacture the same product

again and again.

4

Compliance to critical temperature limits

In food and beverage processes that follow GMP and HACCP guidelines, you could be wasting energy simply by using basic or standard controllers. The problem with these controllers is the wide variation in accuracy levels. When you are not sure of the accuracy, you over compensate by a degree or two to make sure you are always within your critical

limits.

By investing in Precision PID control with accurate Inputs and Outputs, and better rejection to noise, you can be sure that the temperature you set is the temperature you get, and that you are meeting your limits while getting ROI by reducing your energy bills over the lifetime of the controller. Other useful features to look for are alarms and communication protocols that help

to inform you when a critical limit has been reached. Modern control products with embedded Ethernet communications are available with SMTP server functionality for sending emails when an alarm has triggered and have webservers built in so you can view what’s going on from a PC, tablet or Smartphone using a web browser. It is worth mentioning that in some

processes the data needs to be securely recorded and stored for a length of time. While this is much simpler nowadays using a digital data logger, recent innovations built into precision PID control products include secure recording along with crystal clear colour TFT displays and wash down fronts. Ideal for food and beverage applications like dairy and meat processing where recording is required, this type of all in one box solution can be the most cost effective solution.

To help maintain accuracy levels in your process year round, several reputable companies also provide services such as Calibration, Temperature Uniformity and System Accuracy Tests (SATs) at regular intervals, to ensure that temperature measurement products and systems are not drifting over time. These issues are even more important for manufacturers

and processors who export product, for example to the US who need compliance to standards such as FDA 21CFR Part 11 and FDA 21CFR Part 113.

5

Packaging Problems

Some types of packaging are difficult to bond together such as when bonding film to plastic. The time, temperature and pressure are crucial to the heat sealing process to ensure a quality seal that retains its integrity, and basic controllers are not up to this job which can lead to wastage of time, product and packaging. The temperature at the point of the seal needs to be accurate and uniform in combination with the mechanical pressure and time of contact.

A precision PID controller is the best choice for repeatable reliable seals and often, along with the temperature controller, a Programmable Logic Controller (PLC) is used to provide the control of the machine . PLCs are now available with precision control built in and these all in one box solutions are the most cost efficient way to create a repeatable packaging process which optimises the output of the machine.

6

Boiler efficiency

The energy used to supply hot water and steam is one of the biggest contributors to costs in food and beverage manufacture. As the UK government moves towards carbon-free energy generation it is expected that companies will move towards Electric Boilers as a solution to reduce carbon emissions. Basic boiler control can be inefficient if water and steam are not

required constantly so spending a bit more for tighter control that can deal with demand when you need it will give better efficiency.

Some food manufacturers have already made the decision to move to electrically heated boilers to help reduce their carbon footprint. Used in combination with modern power controllers that provide firing modes to suit different types of heaters and algorithms to better manage boiler loads across the plant, they are the way forward for companies who are serious about their commitment to green initiatives and directives like ESOS.

7

Plant Energy Usage

The food and drink processing industry is the fourth highest industrial energy user in the UK. Energy suppliers provide energy on a tariff and in badly managed plants it is possible to draw more energy at certain times than your tariff allows. This can result in hefty fines. The simple answer is better power control and modern thyristor controllers are the key. These new smart devices are available with a large variety of industrial communications which allows them to communicate with each other across the plant. Special algorithms for managing and spreading loads across the plant help make the best use of your energy and keep your finance managers happy by operating within your specified tariff.