< Company News

ORIFICE PLATE ASSEMBLY SOLUTION – THE NSI OPA

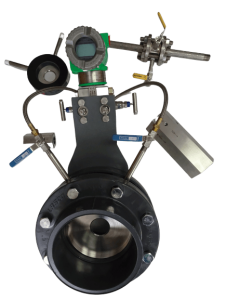

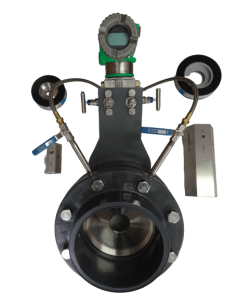

December 9, 2019Neal Systems has teamed with Lambda Square to create the NSI Orifice Plate Assembly (OPA), a pre-assembled, simplified flow measurement solution.

NSI’s team of engineers are here to help with the challenges of specifying, sizing, and assembling a total differential pressure flow-based measurement package.

Our custom-designed Orifice Plate Assembly, the NSI OPA, solution utilizes a Lambda Square orifice plate, a high-accuracy Foxboro by Schneider Electric differential pressure transmitter (just one, not two!), and a pre-fabricated flange assembly containing all necessary connection materials.

Most flow projects utilizing an orifice plate often have three major challenges:

- Two differential pressure transmitters are typically required for wide range flow applications. Traditional DP transmitters have poor accuracy on the low-end of the scale. This causes significant errors in the flow calculation.

- Inaccurate process conditions can result is poorly sized orifice plates

- Customized parts often have long lead-times leading to long down-times

The Neal Systems Orifice Plate Assembly has been engineered to overcome these three challenges.

Our solution solves the first issue of needing two transmitters and flow calculation errors by utilizing a single differential pressure transmitter that has a 0.025% reading accuracy across 88% of the full range – the Foxboro by Schneider Electric IDP50S. Reading accuracy means the error decreases as the measurement decreases. Using the IDP50S means that for the vast majority of flow applications, you do not need a second transmitter for low-flow. In addition, the flow calculation has the same superior accuracy across the 88% of the usable transmitter range, not just at the measurements high point.

The second challenge, inaccurate process conditions, is addressed by our OPA design form, which can be viewed HERE. Our team of application engineers will gather your information and design the optimal orifice plate and options for your application. We will also provide a size up and size down in order to have a back-up plan should conditions change.

And finally, our solution to long lead times is handled by utilizing mostly stock parts for all of our assembly – the transmitter, 3-valve manifold, orifice plate, and mounting assembly are all stocked items that can be quickly ordered replaced and installed should there be an issue.

Additional Options

The NSI Orifice Plate Assembly has an additional option for steam applications. For saturated steam applications we can convert flow to mass by adding a Eurotherm by Schneider Electric Nanodac. The Nanodac can generate a saturated steam table with inputs for flow, pressure, and temperature.